Applications

Abrasive Materials can assist you with various metallic abrasives to determine the best fit for your production needs. Whether your process is as simple as cosmetic blast cleaning, as sophisticated as peening to aerospace specifications or merely removing paint from a critical surface we can help.

Our team represents over 60 years of experience in the air blast and wheel blast industries. Use our experience and free sample processing service to determine which of our cut wire or cast products best suits your finishing requirements.

Contact Abrasive Materials today so that we can assist you with developing a process that best fits your finish expectations. Our sample processing service is available to you free of charge.

Blast cleaning can either be accomplished in an air blast system or a wheel blast unit. Abrasive Materials supplies many products well suited for blast cleaning applications. Many of our products are utilized for blast cleaning when ferrous contamination is of concern. Ferrous contamination can occur as ferrous residue is deposited on the surface of parts as a result of being blasted with standard steel shot or steel grit. Blast cleaning can be used to remove scale, rust, contaminants or for cosmetic finishing.

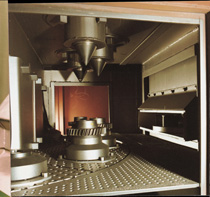

Abrasive Materials can provide technical assistance and expertise for blast cleaning. We provide assistance with media selection and process development. Our sample process facility utilizes the most up to date wheel blasting equipment as well as air blasting equipment. We can sample process any part in any media we offer so you can determine which finish and application best suits your requirements.

Abrasives typically used for blast cleaning include:

Abrasive Materials supplies many products well suited for deburring applications. Deburring can either be accomplished in an air blast system or a wheel blast unit. Blasting is an effective method to remove difficult burrs or cosmetically finishing parting lines from a casting process. Abrasive Materials offers many products for deburring where ferrous contamination is of concern.

Abrasive Materials can provide technical assistance and expertise for deburring. We provide assistance with media selection and process development. Our sample process facility utilizes the most up to date wheel blasting equipment as well as air blasting equipment. We can sample process any part in any media we offer so you can determine which finish and application best suits your requirements.

Abrasives typically used for deburring cleaning include:

Deflashing can either be accomplished in an air blast system or a wheel blast unit however wheel blasting is the more commonly used method for deflashing. Abrasive Materials supplies many products well suited for deflashing applications. Many of our products are utilized for deflashing when ferrous contamination is of concern. Ferrous contamination can occur as ferrous residue is deposited on the surface of parts as a result of being blasted with standard steel shot or steel grit.

Abrasive Materials can provide technical assistance and expertise for deflashing. We provide assistance with media selection and process development. Our sample process facility utilizes the most up to date wheel blasting equipment as well as air blasting equipment. We can sample process any part in any media we offer so you can determine which finish and application best suits your requirements.

Abrasives typically used for blast cleaning include:

Abrasive Materials offers conditioned cut wire products for shot peening applications. Whether you are peening to aerospace specifications or peening gears, Abrasive Materials has a variety of products to meet your requirements. We have products that comply with SAE J441 and AMS 2431 referencing metallurgy, shape, hardness and size. We also offer Type I, Type II or Type III conditioned material.

Depending on your specification, peening can either be accomplished in an air blast system or a wheel blast unit. Many of our conditioned cut wire products are utilized for peening when damage to your parts due to the splitting or fracturing of cast products often occurs. Conditioned cut wire media will not fracture or split as cast products tend to, however they maintain their rounded shape and will delaminate with wear.

Abrasive Materials can provide technical assistance and expertise for shot peening processes. We provide assistance with media selection and process development. Our sample process facility utilizes the most up to date wheel blasting equipment as well as air blasting equipment. We can sample process any part in any media we offer so you can determine the peening intensity and coverage that best suits your requirements.

Medias typically used for blast cleaning include:

Paint Stripping can either be accomplished in an air blast system or a wheel blast unit. Abrasive Materials supplies many products well suited for paint stripping with zinc cut wire being the most widely used product for cleaning paint hooks or de-painting parts. Zinc cut wire does an outstanding job of removing various coatings without damaging the surface of the parts.

Abrasive Materials can provide technical assistance and expertise for paint stripping. We provide assistance with media selection and process development. Our sample process facility utilizes the most up to date wheel blasting equipment as well as air blasting equipment. We can sample process any part in any media we offer so you can determine which finish and application best suits your requirements.

Abrasives typically used for blast cleaning include: